The application value of PTC heater technology in modern heating equipment

As a mature solution in the field of electric heating, PTC heaters have been gaining increasing attention in the home and commercial markets in recent years. Relying on the characteristics of thermistor ceramic materials, it realizes automatic temperature control and energy efficiency adjustment during the heating process, bringing users a safer, energy-saving and convenient heating experience. In this field, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. has gradually established its professional position in the global market with years of manufacturing experience and stable international cooperation.

The core of the PTC heater lies in its thermistor ceramic element, which increases its resistance as the temperature rises, forming a self-limiting temperature mechanism. This feature allows the heater to maintain stable output without the need for a traditional thermostat during operation, avoiding the risk of overheating and extending its service life. Unlike traditional heating equipment, PTC heaters automatically reduce power output after the temperature reaches the set value, thereby effectively saving energy, especially for long-term operation scenarios.

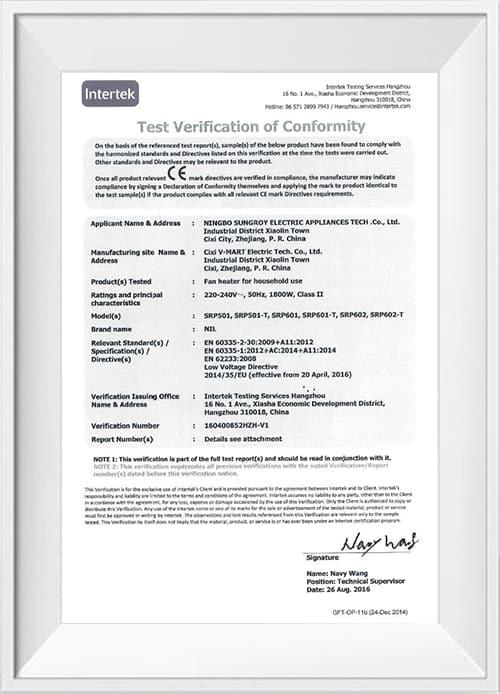

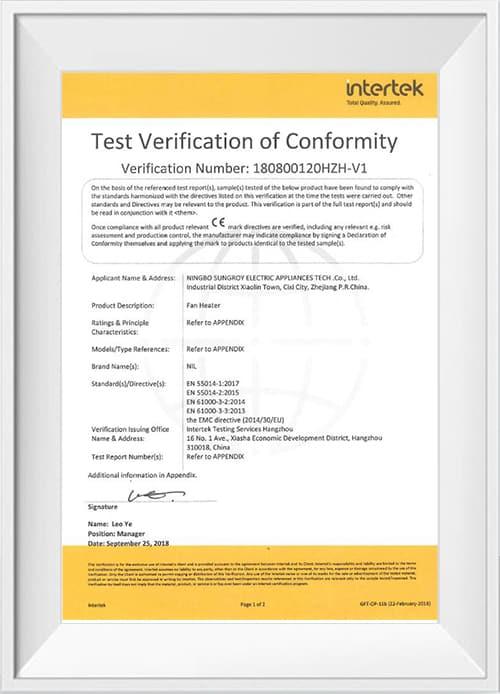

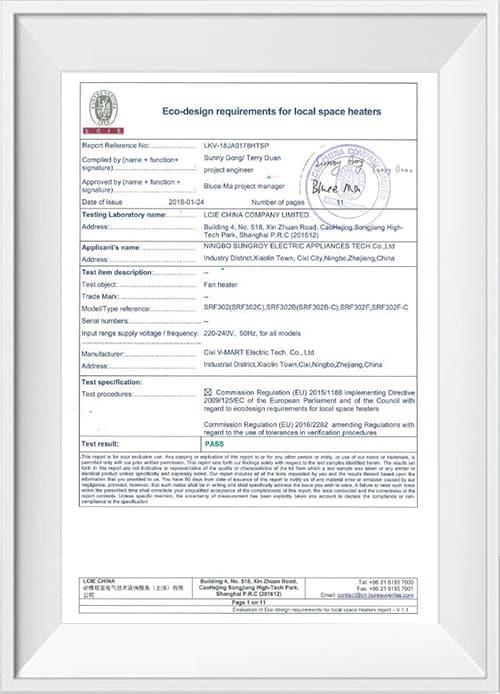

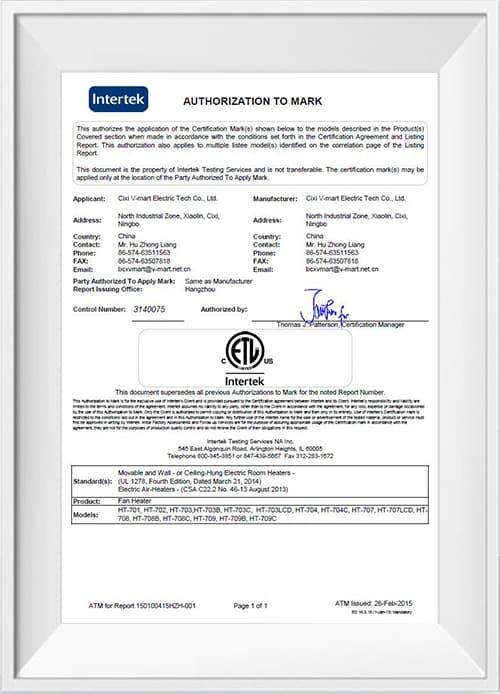

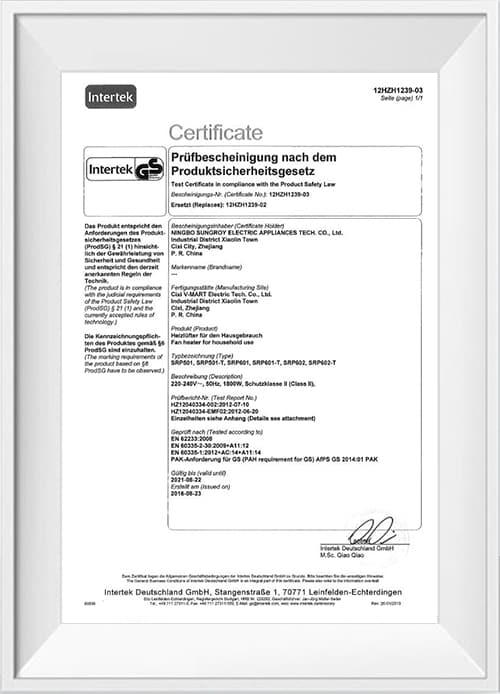

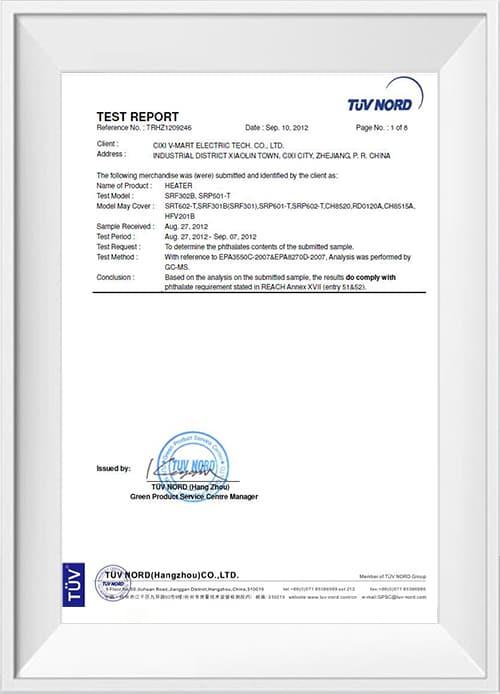

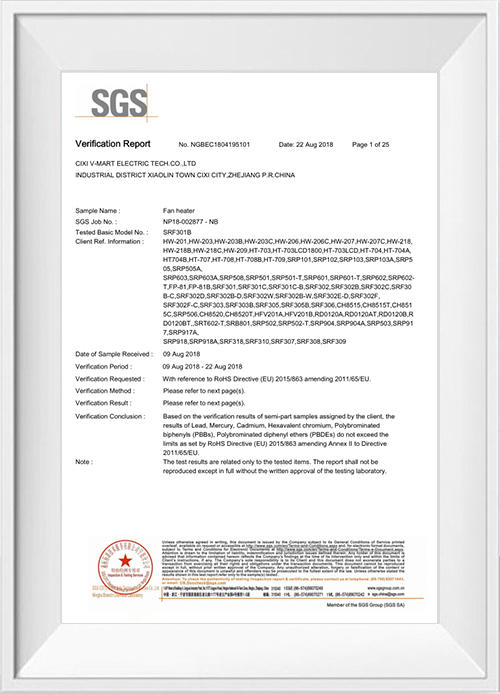

Since its establishment, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. has focused on the design and production of PTC tower heaters, with independent factories and a complete quality management system. The company's products have passed many international certifications such as CE, GS, RoHS, ETL, SAA, etc., and are exported to many countries and regions such as Europe, America, Oceania and the Middle East, and are deeply trusted and favored by customers. The factory has also passed many system audits and certifications such as BSCI, ISO, GSV, QVC, etc., and maintains stable standards in production, quality inspection and after-sales.

The tower-structured PTC heater has been the focus of attention in the market in recent years. It adopts a vertical shape, with air ducts and air outlet structures, which can efficiently realize vertical air supply and meet the needs of various indoor places such as homes, offices, and hotels. This type of product is usually equipped with multi-speed temperature control, timing functions and automatic shaking air supply devices, which not only saves space but also improves the thermal efficiency experience. Ningbo Sungroy Electric Appliances Tech. Co., Ltd. has rich design and manufacturing experience in this product line, and can customize a variety of appearance and functional versions for customers in different regions.

Under the changes in the global energy structure and the trend of energy conservation and environmental protection, PTC heaters have shown greater market potential. It does not rely on open flames, does not consume oxygen, and is pollution-free and low-noise during operation, making it more suitable for the modern green life concept. Whether in daily home heating, electrical heating assistance, industrial small equipment and other fields, the application scope of PTC technology is constantly expanding. Ningbo Sungroy Electric Appliances Tech. Co., Ltd. is a representative enterprise in this trend. With stable manufacturing capabilities and international cooperation foundation, it continues to promote product diversification and market penetration.

The company also provides OEM and ODM services to global customers, providing comprehensive support from structural design, function setting to appearance customization. Through flexible customization capabilities and strict quality control, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. has helped many customers establish their own brands and successfully enter the local market.

As an electric heating product that takes into account safety, energy saving and technological maturity, PTC heaters are gradually becoming an important part of the heating industry. With years of accumulation in the industry, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. will continue to explore new materials, new structures and new functions, and continuously promote electric heating technology to a higher level.

Technical characteristics and market application analysis of PTC heaters

PTC heaters are electric heating elements made of positive temperature coefficient (PTC) materials. This technology automatically adjusts the current through the resistance of ceramic materials as the temperature changes, ensuring good self-protection during the heating process. Because of this, PTC heaters excel in safety and energy efficiency and are suitable for many fields. As a professional manufacturer, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. has been committed to the research and development and production of such products for many years, and has accumulated rich experience and a good industry reputation.

The core advantage of PTC heaters lies in their material properties. The resistance of ceramic elements increases rapidly when the temperature rises, which automatically reduces the current and avoids overheating. This not only improves the safety of the product, but also effectively reduces energy consumption, which meets the requirements of energy conservation and environmental protection in modern society. In addition, PTC heaters have a compact structure and a small size, which makes them easy to integrate into various electrical appliances, providing greater flexibility for product design.

Ningbo Sungroy Electric Appliances Tech. Co., Ltd. mainly produces a variety of heating products including PTC tower heaters, with a complete manufacturing system and strict quality control. The company's products have passed a number of international certifications including CE, GS, RoHS, ETL, SAA, etc., ensuring that its products not only meet domestic standards, but also meet the needs of the international market. With reliable product quality and professional services, the company has won the trust of customers in many countries and regions around the world, especially in Europe, North America, Australia and the Middle East.

As an experienced company in the industry, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. also provides customized services, including OEM and ODM. The company is able to design PTC heaters of different powers, sizes and functions according to customer needs to meet the needs of a diverse market. This flexible customization capability provides strong support for customer brand building and market expansion.

The application range of PTC heaters is very wide. In home heating equipment, tower heaters have become an ideal choice for winter heating due to their uniform air supply and stable temperature control. In industrial equipment, PTC heating elements are also used for auxiliary heating to ensure the normal operation of equipment in low temperature environments. The heater's flameless design reduces safety hazards and is also suitable for use in environments with high requirements for air quality.

Environmental protection and energy saving have become important development directions for today's electrical industry. The low power consumption and automatic temperature limit function of PTC heaters are in line with this trend, helping users reduce power consumption and carbon emissions. Ningbo Sungroy Electric Appliances Tech. Co., Ltd. actively responds to the global call for environmental protection by continuously improving its technical level and promoting the development of products in the direction of high efficiency and energy saving.

The company not only focuses on product research and development, but also attaches importance to after-sales service and customer experience. By establishing a complete after-sales system and responding to customer feedback in a timely manner, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. ensures that every product can operate stably and reliably. Years of experience have enabled the company to maintain its leading position in a highly competitive market environment.

PTC heaters occupy an important position in the field of modern electric heating due to their advantages such as high safety, good energy efficiency and compact structure. As a professional manufacturer, Ningbo Sungroy Electric Appliances Tech. Co., Ltd. provides high-quality products and customized services to global customers with rich industry experience and advanced manufacturing technology, and promotes the continuous advancement and application expansion of PTC heating technology.

English

English 中文简体

中文简体 Français

Français Español

Español Language

Language